Tanks / Vats

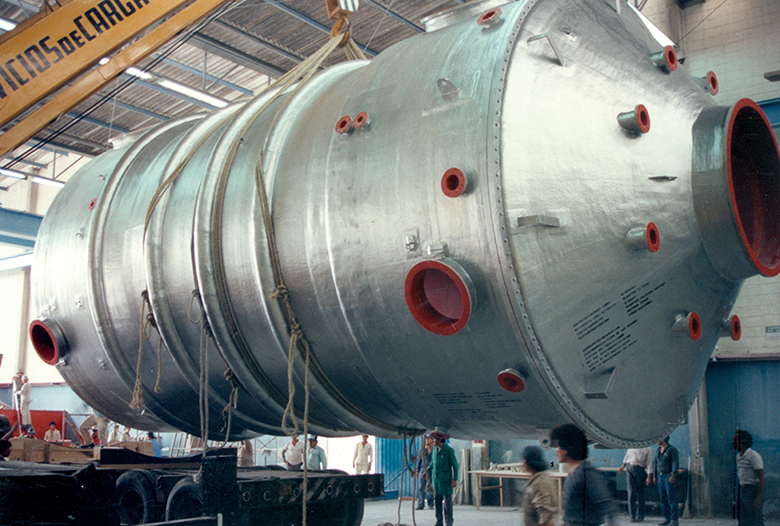

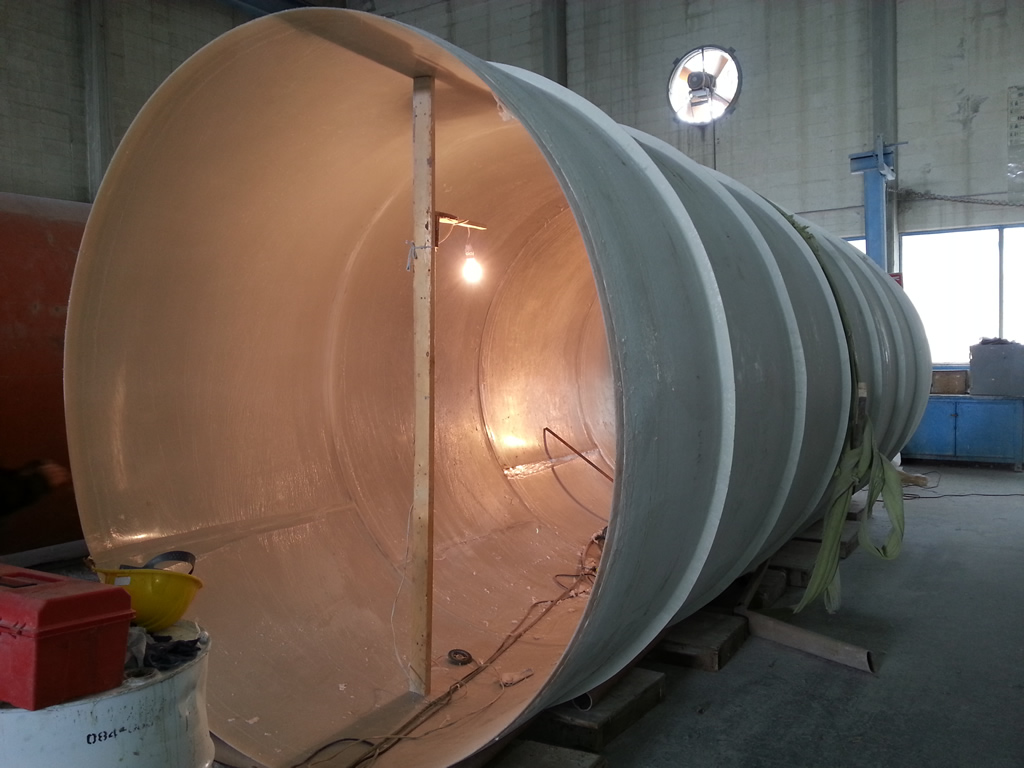

• Description: Containers for storage of liquids, which may have a horizontal, vertical, conical, rectangular or cylindrical configuration as required for the process.

• Design ranges: tanks are classified based on the role they play in a process and the conditions under which they operate, these can be:

a. Storage: we guarantee greater resistance to corrosion with the correct selection of the construction material, this may be a resin reinforced with fiberglass and/or a liner coated with fiberglass.

b. Pressure or vacuum: each piece of equipment is designed according to the specific conditions of the process and for each case there is a memory calculation that gives us as a result the thickness required to obtain ideal performance.

c. Reaction: the equipment is built with accessories to receive equipment and instruments, as well as necessary internal elements for each specific process.

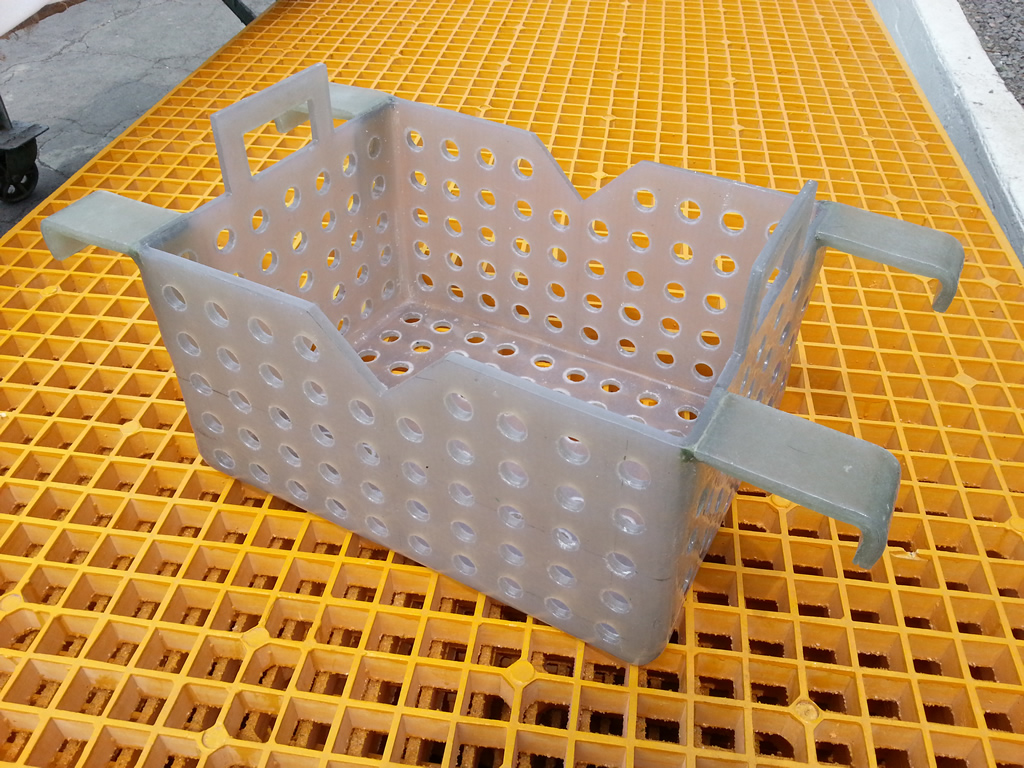

d. Vat: used for thermal or chemical treatment within the industry this kind of process can be corrosive, thus reinforced thermoplastic materials are an excellent solution.

Tanks are designed to withstand temperature, pH and pressure by making a correct choice of material. Within the chemical industry the following materials are commonly used:

Carbon Steel, Stanley Steel, FRP, PP, PE, PVC, CPVC, PVDF, ECTFE, PFA, among others.

Volume range: 0.3 - 200 m3 in equipment manufactured in our facilities and up to 1000 m3 in equipment manufactured in the site.

• Applications: Industrial plants (metallurgical, chemical, petrochemical, pharmaceutical, etc.) shopping centers, hospitals.

• Benefits:

a. Equipment with excellent chemical resistance.

b. Light-weight and easy to install.

c. Low maintenance cost.

d. Manufacturing equipment with LAPSOLITE guarantees it to be the best option, as it is the first producer of reinforced plastic in Mexico (since 1953).

ENGLISH

ENGLISH